- Currently this product is Unavailable.

Related Products of Stoner Anti Stick Coating-1 Can

Stoner B-505 Polyoff Polyurethane Remover, 1 gallon can

Stoner B-505 Polyoff Polyurethane Remover, 1 gallon can

Extra powerful, time-saving formula cleans molds and tools with ease. Completely removes cured polyurethane, mold release, and other build-up from tooling, molds, and machinery. Use only on steel, aluminum and other metal tooling

Directions for Use:

Recommended Procedure:

Wear rubber gloves and safety goggles to protect skin and eyes. Saturate the mold build-up with B-505 and allow to soak for about 8-10 hours. Soaking time may vary depending on the degree of build-up and temperature of mold. Allow B-505 to soak in until build-up easily wipes away with a rag or soft parts cleaning brush. Difficult areas may require a second application, 24hours of soaking, or scrubbing with soft cleaning brush or rag. Remove excess cleaner with a rag or allow to airdry. B-505 is a strong cleaner which may be harmful to certain plastics, paints, or other solvent sensitive materials. Always test for compatibility before using. Immediately after use, let B-505 evaporate from cloths or other applicators in a well-ventilated area, away from sources of ignition. Collect and dispose of material, rags, and applicators in metal containers in accordance with all local, state, and federal regulations.

Storage and Handling:

Keep container tightly closed when not in use. Store in a cool, dry, well-ventilated area away from all sources of ignition. Avoid prolonged or repeated breathing of vapor. Avoid prolonged or repeated contact with skin. Use with adequate ventilation. Do not use near ignition sources. Consult SDS for additional safety information.

Dynasolve CU-6 1g

Dynasolve CU-6 1g

Dynasolve CU-6is a non-gelling, higher flash point version of CU-5, and is recommended for both flushing and cleaning, especially in applications in which liquid isocyanates are present either prior to cleaning, or will be introduced after cleaning (such as in a mixing tank).Dynasolve CU-6is non-chlorinated, nonflammable (by U.S. Department of Transportation definition), non-carcinogenic, and non-ozone depleting. It replaces and improves on the performance of commodity solvents such as methylene chloride, acetone, methyl ethyl ketone (MEK), and 1,1,1-trichloroethane.Dynasolve CU-6can be used for extended periods, tolerate high resin loadings, and will reduce disposal costs. It is also recyclable via vacuum distillation.

Directions for Use:

For Flushing: Use Dynasolve CU-6as you would normally use any other flushing solvent. Mild heating of the solvent will product faster results. The use of compressed air for agitation of the solvent will also help to facilitate cleaning. If excessive amounts of liquid isocyanates are present, Dynasolve Iso-Neutralizer must be used first. Failure to use the Iso-Neutralizer may lead to gelling of the flushing solvents.

For Cleaning: Immerse parts to be cleaned in Dynasolve CU-6. Let soak until residue is loosened and can be wiped or brushed off. Then rinse parts with water and dry. Mild heating of the solvent to 130-150° F, and/or the use of ultrasonics will produce faster results. Mechanical filtering of larger urethane particles using a cheesecloth or metal mesh filter will help extend the life of the solvent. For the most difficult applications, more aggressive (reactive) solvents are available.

Materials of Construction:

Recommend: Teflon, butyl rubber, silicon rubber, Kalrez, mild steel, Halar, melamine, Nylon 101, polyethylene, polypropylene, Ryton (150°F or less).

Avoid: Viton, PVC, ABS, Buna-N, Durel, Hypalon, Kynar, Lexan, Lucite, Neoprene, Noryl EN-265, Noryl 731, PET, phenolic, polyester, polysulfone, polyurethane, Ultem, Valox.

Cautions:

Dynasolve CU-6contains powerful organic solvents. It is harmful if inhaled or swallowed. Avoid breathing vapors or mist. Keep away from heat and flame. Avoid contact with eyes and skin. Wear gloves, safety glasses, and protective clothing when handling. Use with adequate ventilation.

- Dynasolve CU-6 is especially effective for flushing mixing and metering equipment and feed lines, as it quickly and completely cleans polyols, crystallized isocyanates, and other urethane intermediates. However, in cleaning of isocyanate sides of equipment, Dynasolve Iso-Neutralizer should be used first if excessive onlyamounts of liquid isocyanates are present. Dynasolve CU-6 will not gel in contact with liquid isocyanates, but if limited amounts are present.

- Dynasolve CU-6 is very effective in penetrating, loosening, and removing cured urethane foam deposits andbuild-up from mixing heads, troughs, conveyor parts, side walls, rollers, foam cutting devices and molds.

- Dynasolve CU-6 will remove all types of urethanes: flexible, rigid, elastomers, molded, and adhesives. It iseffective for both MDI and TDI esters and ethers.

- Dynasolve CU-6 will quickly and completely clean residual cured polyurethane reactive hot melt (PURHM)urethane adhesives from roll coating equipment. It will also remove these same reactive hot melts fromdispensing equipment.

- Dynasolve CU-6 is excellent for the removal of polymer-based inks from rollers in flexographic printingequipment.

- When heated, Dynasolve CU-6 will also clean many types of epoxies and other adhesives.

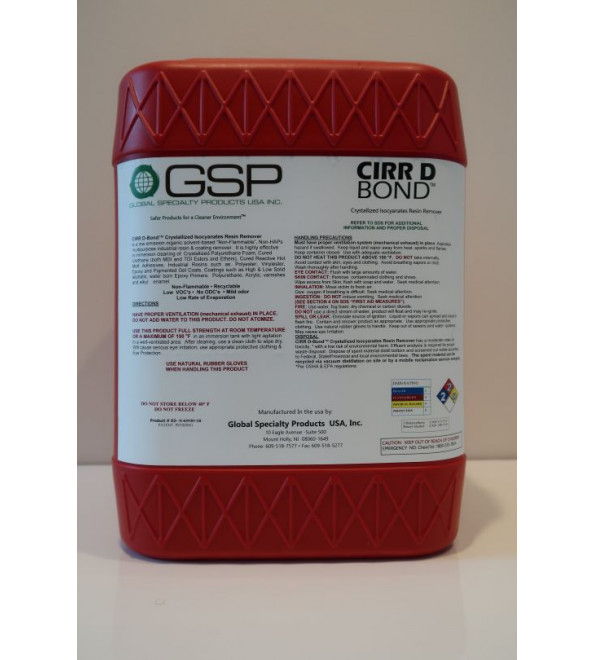

GSP Cirr D Bond: 5 Gallon Pail

- ONLY IMMERSION CLEANING FOR BUILD UP OF HARDENED ISO(A) & INDUSTRIAL RESINS AT A MAX OF 140 °F

- SAFE ON ALL FERROUS & NON-FERROUS METALS

- DENSER & MORE AGGRESSIVE FORMULA

GSP Cirr D Bond: 1-Gallon Jug

- ONLY IMMERSION CLEANING FOR BUILD UP OF HARDENED ISO(A) & INDUSTRIAL RESINS AT A MAX OF 140 °F

- SAFE ON ALL FERROUS & NON-FERROUS METALS

- DENSER & MORE AGGRESSIVE FORMULA

GSP Surf X Flush: 5 Gallon Pail

- FLUSHING, LOW-PRESSURE SPRAY FOR LARGE AMOUNTS OF HARDENED ISO (A) & REMOVING OVERSPRAY FROM UNPAINTED SURFACES

- FLUSHING POLYOL (B) & ALL OTHER URETHANE INTERMEDIATES

- IMMERSION CLEANING FOR RESIN & POLYMERS MAX OF 140 °F

- MEDIUM DENSITY

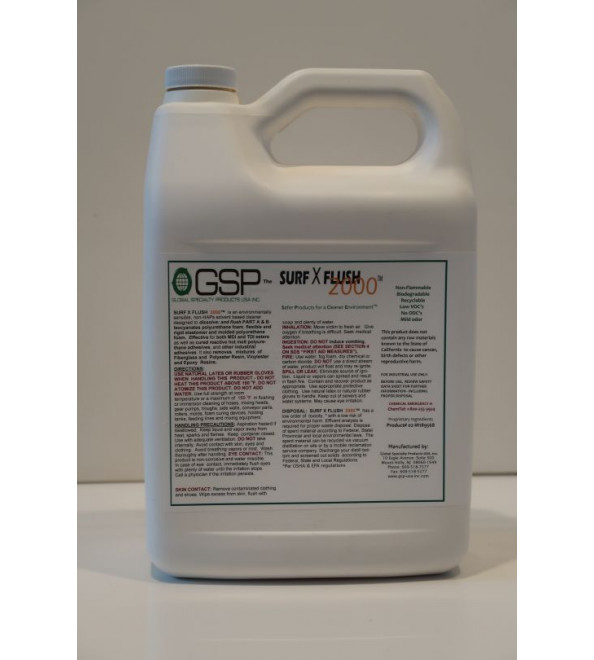

GSP Surf X Flush: 1-Gallon Jug

- FLUSHING, LOW-PRESSURE SPRAY FOR LARGE AMOUNTS OF HARDENED ISO (A) & REMOVING OVERSPRAY FROM UNPAINTED SURFACES

- FLUSHING POLYOL (B) & ALL OTHER URETHANE INTERMEDIATES

- IMMERSION CLEANING FOR RESIN & POLYMERS MAX OF 140 °F

- MEDIUM DENSITY

GSP Surf X Flush: Go Green Wipes

- 90 PRE-MOISTENED 12" X 12" POLYPROPYLENE WIPES WITH THE POWER OF GSP USA'S SOLVENTS

- QUICK, EASY, SAFE & EFFECTIVE WAY TO REMOVE SINGLE COMPONENT ISO (PART A & B) RIGID & MOLDED POLYURETHANE FOAM

- MDI & TDI ESTERS & ETHERS, CURED REACTIVE HOT MELT, POLYURETHANE ADHESIVES & OTHER INDUSTRIAL SOILS

- MIXTURES OF FIBERGLASS & POLYESTER RESIN, VINYLESTER & EPOXY RESINS

- WIPE OFF HOSES, BUILDUP OF MIXING HEADS, GEAR PUMPS, TROUGHS, SIDE WALLS, CONVEYOR PARTS, ROLLERS, MOLDS, FOAM CURING DEVICES, HOLDING TANKS, FEEDING LINES & MIXING EQUIPMENT

- PERFECT FOR USE IN SMALLER & CONFINED SPACE WORK AREAS

Proper Procedure:

- Pull out one pre-moistened wipe from the bucket and close dispenser with attached cover securely.

- Apply wipe on surface using circular motions to cover the area with solvent.

- If needed, leave wipe on overnight or until surface is cleaned.

- Discard the wipe in accordance with all local, regional, national, provincial, territorial and international regulations. Waste characterizations and compliance with applicable laws are solely the responsibility of the waste generator.

GSP Surf A Lube: 5 Gallon Pail

- USED IN SPRAY EQUIPMENT FOR MID TO LONG TERM STORAGE UP TO 36 MONTHS

- USED IN TRANSFER PUMPS, HOSES, PROPORTIONERS & GUNS

- ALSO ACTS AS A PLASTICIZER, PREVENTING ISO (A) FROM FORMING CRYSTALS

- IDEAL FOR WINTERIZING RIGS & CAN WITHSTAND SEVERE COLD TEMPS WITHOUT FREEZING

- VOC EXEMPT, NON-FLAMABLE & NON-CORROSIVE

GSP Surf A Lube: 1-Gallon Jug

- USED IN SPRAY EQUIPMENT FOR MID TO LONG TERM STORAGE UP TO 36 MONTHS

- USED IN TRANSFER PUMPS, HOSES, PROPORTIONERS & GUNS

- ALSO ACTS AS A PLASTICIZER, PREVENTING ISO (A) FROM FORMING CRYSTALS

- IDEAL FOR WINTERIZING RIGS & CAN WITHSTAND SEVERE COLD TEMPS WITHOUT FREEZING

- VOC EXEMPT, NON-FLAMABLE & NON-CORROSIVE