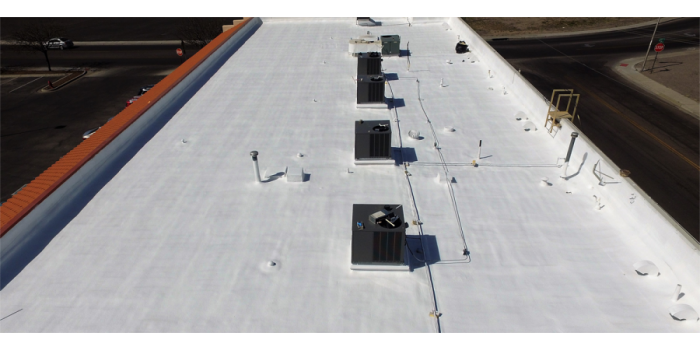

To keep your Spray Polyurethane Foam (SPF) roof performing at its best, it needs protection—from moisture, foot traffic, and harsh UV rays. But how do you ensure long-lasting durability?

The answer: A high-quality protective coating.

Applying a proper coating not only extends the life of your SPF system, but also boosts energy efficiency and reduces maintenance costs.

Let’s break down the most common options so you can choose the right one for your next project:

Silicone Coatings

Acrylic Coatings

Polyurethane Coatings

Choosing the right coating depends on your environment, budget, and specific roof demands. Need help picking the perfect fit? Our team at Profoam is here to guide you.

Once Spray Polyurethane Foam (SPF) is applied to the desired thickness, it needs a protective layer to ensure long-term durability. Two common methods are elastomeric coatings and gravel systems. Both provide crucial protection from the elements and foot traffic, while enhancing the roof’s lifespan.

Elastomeric coatings are the go-to choice for most SPF roofs. They offer:

Popular elastomeric coating materials include:

These coatings can be spray-applied as single- or two-component systems, depending on the product and project needs.

While not as widely used, gravel systems are still a viable alternative. Gravel provides a physical barrier against UV rays and foot traffic and helps insulate the building. However, they tend to be heavier and require more structural consideration. Be sure to consult your SPF supplier before choosing this method.

Cool roof coatings are typically white or light-colored, designed to reflect sunlight and reduce rooftop temperatures. These coatings are especially beneficial in hot climates and can help lower energy costs.

Acrylic Coatings

Silicone Coatings

Choosing between coatings or gravel depends on your budget, climate, and roof usage. Reach out to the experts at Profoam—we’re here to help you make the right call for your SPF roofing system.

Proper maintenance and smart product selection are key to keeping your SPF (Spray Polyurethane Foam) roof system performing at its best. Here’s what to keep in mind:

Like any part of a building, SPF roof coatings require upkeep to maximize their lifespan. Over time, coatings may wear down due to weather and UV exposure. The good news? They can be:

Think of it like repainting your home—it’s a small step that goes a long way in preserving value.

SPF roofing systems expand and contract with temperature changes. To stay in sync, your protective coating must be flexible. This property is measured by something called elongation—the ability of the coating to stretch without cracking.

🔍 Pro Tip:

Before selecting a coating, ask your materials supplier for options that match your local climate and roof movement needs.

Looking for the right roof coating? Profoam offers a wide selection of elastomeric coatings designed for:

Need help choosing? Our team can guide you through the best options based on performance, elongation, and durability.

Your SPF roof is a major investment—protecting it is critical for long-term performance and cost savings. By staying on top of maintenance and selecting the right coating, you’re ensuring decades of durability and energy efficiency.

📞 Contact Profoam today to find the perfect coating solution for your next project.