Federal Tax Credit

November 29, 2022

When it comes to spray foam insulation equipment, many contractors are tempted by low-cost machines promising similar results to premium options. These budget-friendly alternatives can seem attractive for businesses looking to minimize initial expenses.

Cheap spray foam machines often lead to inconsistent application, frequent breakdowns, and costly repairs that can exceed $15,000 annually - far more than investing in quality equipment from the start. Professional-grade machines from Profoam Corporation deliver reliable performance and precise material ratios, ensuring optimal foam properties and reducing material waste.

Every insulation job requires dependable equipment that performs consistently day after day. Quality machines maintain proper temperature control and pressure settings, resulting in better adhesion, thermal resistance, and customer satisfaction - essential factors for building a successful insulation business.

Low-cost spray foam equipment comes with significant hidden expenses and operational challenges that can impact a contractor's bottom line and project quality. Professional-grade machines from established manufacturers like Profoam Corporation deliver superior returns through enhanced reliability and performance.

Entry-level spray foam machines typically cost $5,000-$8,000, compared to $15,000-$25,000 for professional equipment. This price difference attracts many new contractors.

The initial savings often disappear within the first year due to frequent repairs, downtime, and replacement parts. Professional-grade machines maintain their value and operational efficiency for 8-10 years with proper maintenance.

Low-cost machines frequently require replacement within 2-3 years, forcing contractors to reinvest in new equipment. This cycle can cost 2-3 times more than investing in quality equipment initially.

Cheap spray foam machines use lower-grade components that wear out faster. Common failure points include:

Replacement parts for budget machines often take longer to source and may require frequent reordering due to inconsistent quality.

Downtime from equipment failures costs contractors an average of $1,500-$2,000 per day in lost productivity and labor expenses. Professional machines reduce these risks with robust components and readily available parts.

Budget machines struggle to maintain consistent temperature and pressure control, leading to improper foam mixing and application issues.

Material waste increases by 15-25% with cheap equipment due to:

Professional spray foam equipment delivers precise ratio control and consistent application parameters, resulting in better foam quality and reduced material costs.

Project callbacks and warranty claims occur 3-4 times more frequently with low-cost equipment installations, damaging contractor reputation and profitability.

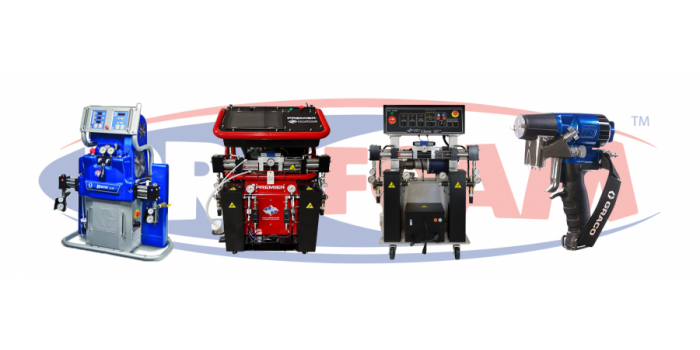

Profoam Corporation sets the industry standard with professional-grade spray foam equipment and comprehensive support services that maximize contractor productivity and project success.

Profoam machines feature precision-engineered components that consistently deliver accurate material ratios and superior spray patterns. The robust construction includes stainless steel heaters and high-pressure pumps rated for 2000+ PSI.

Advanced digital controls enable contractors to maintain exact temperature and pressure settings throughout each application. Real-time monitoring systems alert operators to potential issues before they cause downtime.

The ergonomic design reduces operator fatigue, with balanced spray guns and heated hose assemblies that maintain optimal material viscosity. These features help contractors complete jobs faster with fewer interruptions.

Profoam provides technical support from experienced spray foam professionals who understand jobsite challenges. Factory-trained technicians offer rapid response for maintenance and repairs.

Comprehensive training programs cover equipment operation, troubleshooting, and maintenance procedures. Contractors gain hands-on experience in Profoam's state-of-the-art training facility.

The company maintains extensive parts inventory for same-day shipping on critical components. Service agreements include regular maintenance checks and priority support to minimize equipment downtime.

Local distribution centers across North America ensure quick access to supplies and technical assistance when needed.