Federal Tax Credit

November 29, 2022

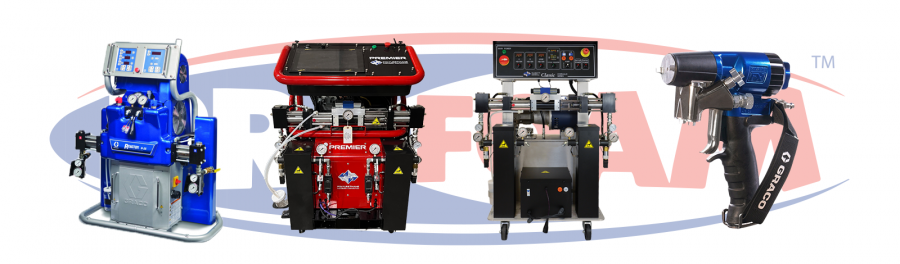

Professional Spray Foam Equipment for Contractors

Professional spray foam contractors know that reliable equipment is the foundation of exceptional insulation services. A complete spray foam equipment setup from Profoam Corporation includes all the essentials—spray foam rigs, proportioners, machines, and guns—engineered to work seamlessly together for superior results.

The success of any spray foam installation project depends on having the right tools. High-quality equipment ensures consistent foam application, accurate chemical mixing, and efficient project completion—all while meeting strict safety standards.

Today’s spray foam applications demand both precision and versatility. Profoam’s comprehensive range of equipment gives contractors the confidence to tackle any project, from residential attic insulation to large-scale commercial roofing systems.

Professional spray foam equipment forms the backbone of successful insulation projects. By combining precision machinery with specialized components, contractors can achieve consistent, high-quality foam applications every time.

Spray foam insulation consists of **two liquid components—**isocyanate and polyol resin—that chemically react when mixed. The foam can expand up to 100 times its liquid volume within seconds of application.

Temperature and pressure control are critical for proper chemical reactions. Professional equipment maintains:

Spray foam comes in two main types:

Each type requires specific equipment settings and spray techniques to achieve optimal performance.

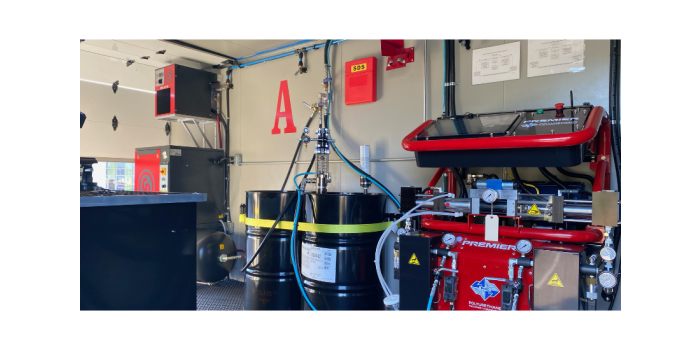

A complete spray foam rig includes several essential components:

Power and air supply requirements:

Material storage: Temperature-controlled storage is essential, typically achieved with electric drum heaters or heated storage areas.

Professional spray foam contractors rely on specialized equipment and tools to deliver efficient, high-quality installations. Proper equipment selection impacts project success, safety, and profitability.

Profoam Corporation offers comprehensive spray foam equipment solutions designed for contractors of all sizes. Their product line includes:

Mobile spray rigs come fully equipped with generators, air compressors, and material storage systems, providing a turnkey solution for immediate project deployment.

Custom configurations are available to match specific project requirements and budget constraints. All equipment meets industry safety standards and includes technical support to maximize uptime and efficiency.

Professional-grade proportioners are the heart of any spray foam operation. These machines precisely mix and heat the two chemical components at the correct ratio and temperature.

Key features:

Machines range from basic models for residential jobs to high-output units for commercial applications.

Spray guns are the critical point of application for foam insulation. Professional-grade guns feature adjustable spray patterns and material flow controls.

Essential spray gun characteristics:

Regular maintenance and proper cleaning extend gun life and ensure consistent spray patterns. Keeping backup guns on hand prevents costly downtime during large projects.

Selecting appropriate spray foam equipment requires careful consideration of project scope and specific technical requirements. The right tools will maximize efficiency and deliver consistent, high-quality results.

Start by calculating your daily foam application volume. Small residential projects may need 20-30 sets per month, while commercial jobs often require 40-60 sets.

Consider your typical job sites and mobility needs. Compact spray rigs work well for residential renovations, while larger trailer setups suit new construction projects.

Your power source availability impacts equipment selection. Some sites require generators, while others have reliable electrical connections.

Budget allocation must account for both initial purchase and ongoing maintenance costs. Quality spray foam equipment from Profoam Corporation represents a long-term investment.

Compare heating capacity across different proportioner models. Professional-grade units maintain consistent temperatures between 125-150°F for optimal foam performance.

Key specifications to examine:

Look for equipment with robust safety features like automatic shutdown systems and pressure balancing technology.

Consider manufacturer support and parts availability. Profoam Corporation provides comprehensive technical assistance and readily available replacement components.

Safe operation and proper maintenance of spray foam equipment protect workers while ensuring optimal performance and longevity of the machinery. Following established protocols and performing regular maintenance checks are critical steps for successful spray foam application.

Personal protective equipment (PPE) is mandatory when operating spray foam machinery. Workers must wear respiratory protection, chemical-resistant suits, and safety goggles.

Maintain proper ventilation in the work area through exhaust fans and fresh air intake systems. Air monitoring equipment should track isocyanate levels.

Essential Safety Checks:

Create designated zones for spray application with clear signage to restrict unauthorized access. Keep emergency response equipment and first aid kits readily available.

Clean spray guns thoroughly after each use with appropriate solvents. Flush material lines according to manufacturer specifications to prevent material buildup.

Daily Maintenance Tasks:

Store chemicals at recommended temperatures between uses. Replace worn parts immediately to avoid equipment failure.

Calibrate proportioners regularly to maintain proper material ratios. Document all maintenance activities and equipment readings in a dedicated logbook.

Keep detailed records of equipment hours and schedule professional servicing at recommended intervals. Test backup systems monthly to ensure reliability.

For any additional information, feel free to contact our team. We are here to help!