Federal Tax Credit

November 29, 2022

A coal terminal in Newport News, VA was dealing with severe water intrusion in a vehicle tunnel beneath an active railroad. Winter freezes made the tunnel impassable, and a void beneath the structure added to the risks.

Jackcrete of Virginia solved the problem in just three days using NCFI’s polyurethane system, filling voids and sealing every leak without disrupting railroad or terminal operations.

The result? A watertight, safe tunnel restored with zero excavation—and an SPFA Industry Excellence Award to prove it.

See how polyurethane injection handled a tough infrastructure challenge.

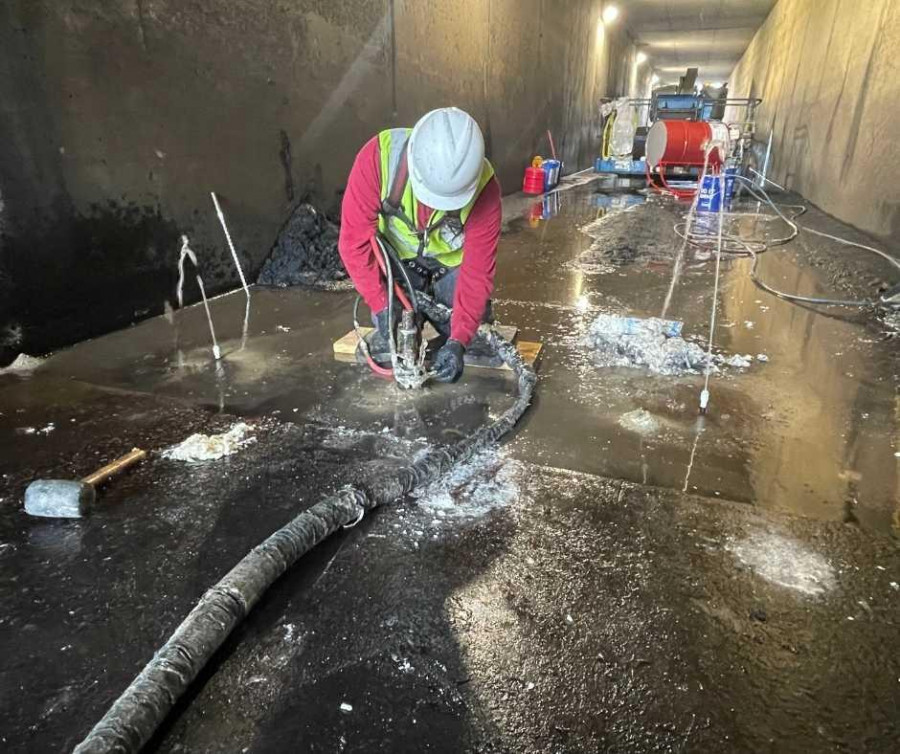

At a coal terminal facility in Newport News, Virginia, a several hundred foot vehicle access tunnel beneath an active railroad was facing severe water intrusion. This single-lane tunnel connected opposite sides of an equipment yard and had long suffered from persistent water infiltration at its joints. Over time, the issue worsened, resulting in standing water on the drive lane floor and visible leaks up to three feet along the tunnel walls.

During winter months, the problem escalated. Water would freeze on the tunnel floor, creating dangerous conditions that rendered the passage unusable for vehicles. Beneath the tunnel, a large void was also discovered, though the primary concern remained the extensive and chronic water intrusion and freeze thaw cycles.

A six-man Jackcrete of Virginia crew was called in to deliver a targeted, efficient repair using polyurethane injection. The repair strategy involved a combination of single and dual component polyurethane systems provided by NCFI Geotechnical:

Technicians worked methodically, injecting polyurethane along the full approach to the tunnel, down each wall, and into every visible leak path—including weep holes and known wet spots. In some areas, injection patterns followed a crisscross technique to thoroughly encapsulate the joints and maximize seal effectiveness.

As the polyurethane was injected, water was actively displaced from beneath the structure—what the crew referred to as “chasing the water.” Laser levels were used to monitor slab elevation throughout the process to ensure no unintended lift occurred. The structure itself had not settled; the objective was to seal the tunnel and reconnect it to surrounding soil without disruption to the slab.